Types and sizes,all have.

Flexible&Rigidity all can choose.

Corresponding to stainless steel and medium carbon steel

Duralumin / Super Duralumin

Rigid coupling

Rigid coupling

Rigid coupling

Flexible coupling-Jaw type

Clamping fixing(Big Shaft Diameter)

GOOFACE(Large shaft diameter)

Duralumin

Flexible coupling-Jaw type

Flexible coupling-Jaw type

Flexible coupling-Jaw type

Flexible coupling-Jaw type

Flexible coupling-Oldham type

Flexible coupling-Oldham type

Flexible coupling-Oldham type

Flexible coupling-Oldham type

Flexible coupling-Oldham type

Flexible coupling-Bellows design

Flexible coupling-Bellows design

Flexible coupling-Metal disk in straight type

Flexible coupling-Metal disk in straight type

Flexible coupling-Metal disk in straight type

Flexible coupling-Metal disk in straight type

Flexible coupling-Metal disk in straight type

Flexible coupling-Metal disk in straight type

Flexible coupling-Jaw type

Flexible coupling-Spiral beam type(for stepping motor)

Flexible coupling-Spiral beam type(for stepping motor)

Flexible coupling-Spiral beam type(for stepping motor)

Flexible coupling-Spiral beam type(for stepping motor)

Flexible coupling-Spiral beam type(for servo motor)

Flexible coupling-Spiral beam type(for servo motor)

SUS303

Rigidity Coupling

Rigidity Coupling

Rigidity Coupling

Rigidity Coupling

Flexible coupling-Jaw type

Flexible coupling-Jaw type

Flexible coupling-Jaw type

Flexible coupling-Jaw type

Flexible coupling-Bellows design

Flexible coupling-Bellows design

Flexible coupling-Spiral beam type(for stepping motor)

Flexible coupling-Spiral beam type(for stepping motor)

Flexible coupling-Spiral beam type(for stepping motor)

Flexible coupling-Spiral beam type(for stepping motor)

Medium Carbon Steel

Flexible coupling-Jaw type

Product introduction

- Coupling is a mechanical device that connects two shafts to drive power and transmits safety moments. .

- Generally, couplings can be divided into two categories: "flexible" and "rigid" couplings.

- When it is difficult to transmit the power, the two shafts are placed in a straight line, or the installation of the two shafts is very simple, a flexible coupling (Flexible Coupling) should be used. The position difference and the function of improving the traditional transmission force characteristics of the system, so even if a slight deviation occurs during installation, the shaft will not be strong, and it is widely used in the market.

- Rigid coupling is a component that cannot cause eccentricity and deflection angle support, and can fix the connected two shafts into one body. Therefore, the concentricity must be very high in use, because the user must try to make the motor rotation and the load shaft in line , That is, the shaft must be strictly calibrated, otherwise the motor will oscillate endlessly during operation. Over time, not only the shaft is prone to fracture due to mechanical fatigue, but also the shaft is heated and worn due to the biased load. The advantage of rigid couplings is that they can reliably transmit torque.

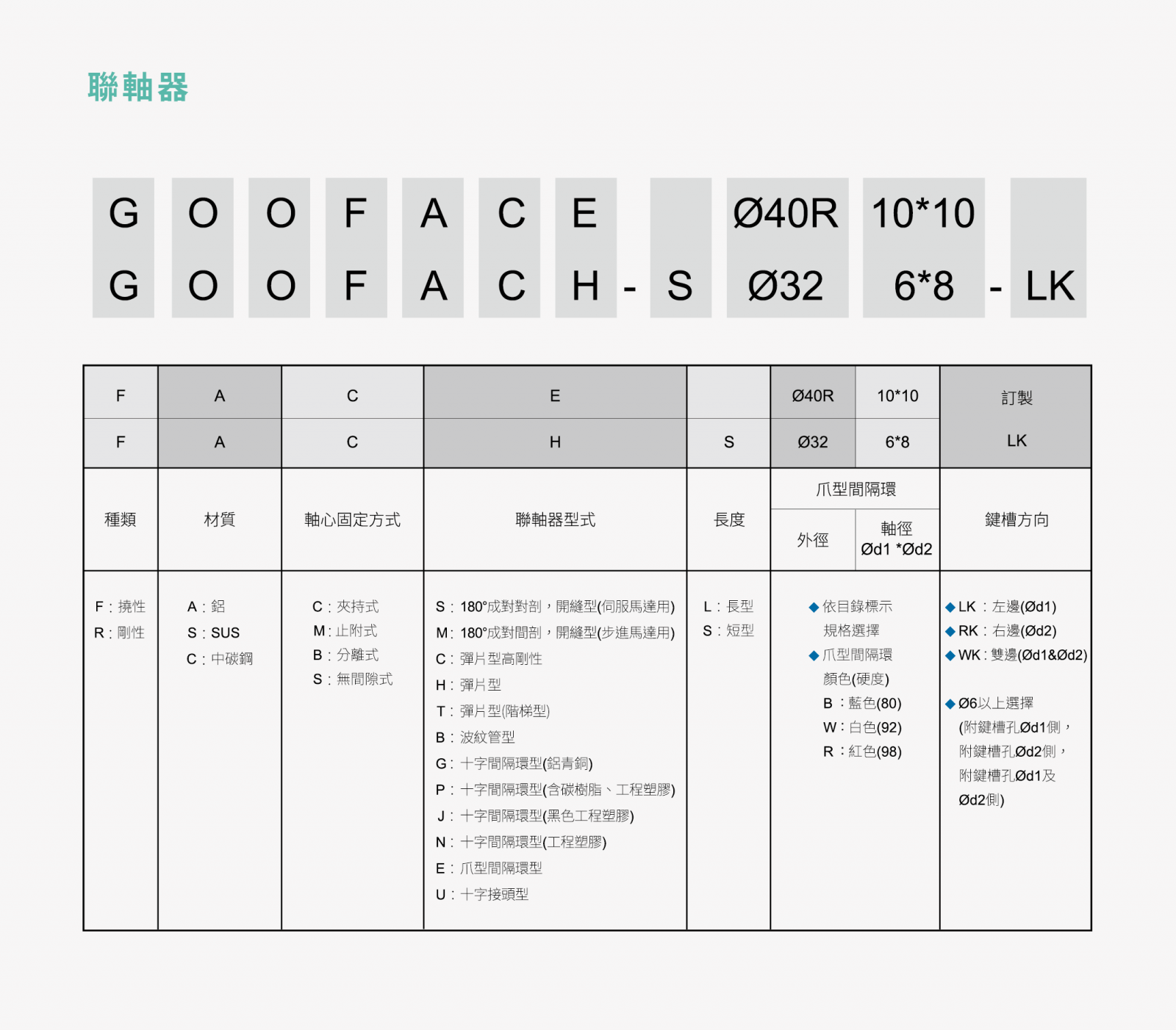

Model description